Alejandra Rivera

Escuela Politecnica Nacional, Ecuador

Biography

Alejandra Rivera is doing her final work in order to obtain her bachelor's degree in Chemical Engineering at the Escuela Politécnica Nacional, Ecuador. She is working as a Research Assistant on the project PIJ 15-16 “Study of the extraction process and characterization of inulin from Ecuadorian tubers by conventional and non-conventional methods” directed by Lorena Jaramillo.

Abstract

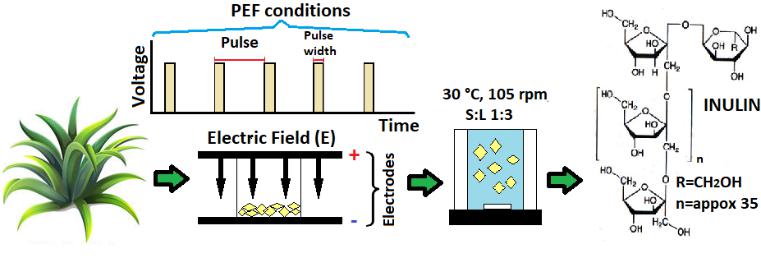

Cabuya (Agave Americana) is an Andean native plant which has not been much studied, although it has valuable compounds such as inulin, saponins, steroids, terpenes and tannins. Inulin is a storage carbohydrate which belongs to fructans. Due to health benefits, inulin has become widely used in the food industry. Commonly, inulin is extracted using conventional thermal method (CTM) which requires high temperature (70–80 ºC) and extraction time of 1.5-2 h. Novel extraction methods have attracted attention, because they are less energy consuming and more efficient. A remarkable method is pulsed electric fields (PEF), a pretreatment which reduces considerably extraction time and temperatures (20–40ºC), becoming a green process that fits with the sixth principle of green chemistry. This work aimed to extract soluble matter from Ecuadorian cabuya meristem using PEF at several operating conditions. Cabuya meristem was sliced into pieces of 20 x 20 x 3 mm; then two parallel samples were prepared, one with PEF pretreatment and the other without PEF. Immediately, both samples were subjected to extraction by stirring in water. Finally, PEF and CTM extraction times and energy consumption were compared. The results showed that the best PEF pretreatment conditions were 2 cm of electrodes distance, 20% of pulse width, 1 kHz of frequency and an electric field of 2 500 V/cm. When PEF was applied at the best conditions during 1 s at 30ºC, pretreated samples raised the same soluble matter yield than non-pretreated, spending less time and energy. Extraction time reduced from 50 to 20 minutes by applying PEF, and the energy required by PEF extraction method represented 40% of the consumed energy by CTM. Thus, PEF technique has a significant effect on the extraction process efficiency, showing to be promising as green technology to chemical industry process.